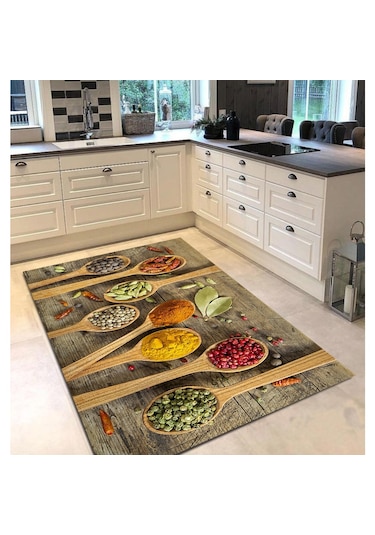

Mutfak Baharat Baharat Kaşık Desen Halı Kilim Mutfak Giriş Paspas Koridor Kaymaz Dekoratif Zemin Mat Alan Kilim Hediye satın almak online / Ev & bahçe | Canasansor.com.tr

miqna Mutfak halısı, kaymaz mutfak yolluğu, yıkanabilir mutfak halısı, siyah mutfak paspası, (siyah, 80 x 200 cm) : Amazon.com.tr: Ev ve Yaşam

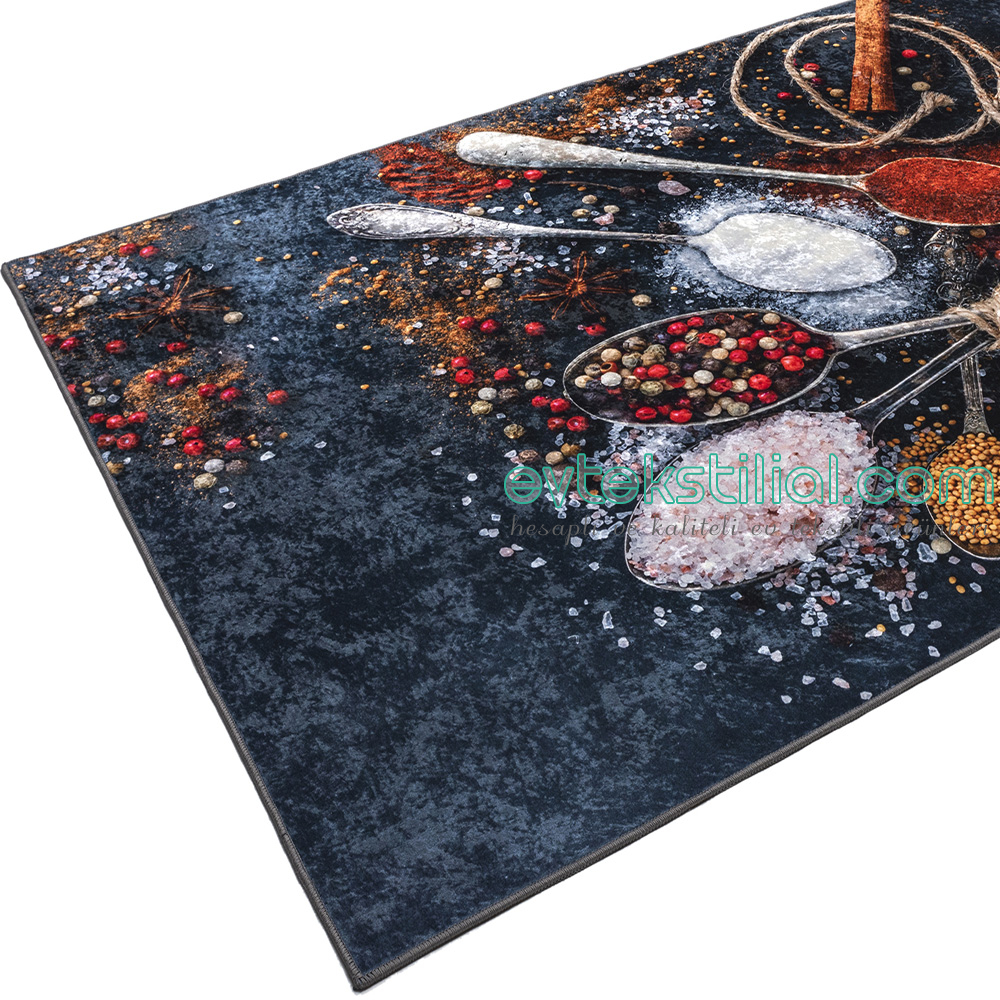

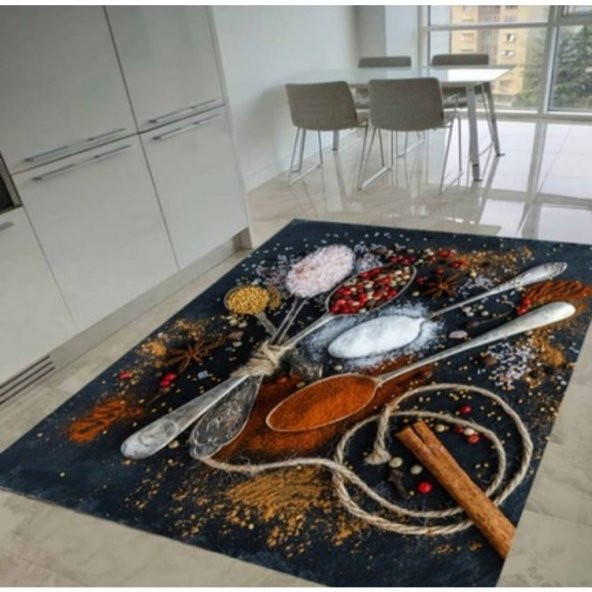

Bonny Home 3D Kaşık Desen Kaymaz Deri Taban Mutfak Halısı Kilimi Yolluk (100x200) : Amazon.com.tr: Ev ve Yaşam

on the clouds Gri Çatal Bıçak Kaşık Figürlü Yıkanabilir Kaymaz Taban Leke Tutmaz Modern Mutfak Halısı Ve Yolluk Fiyatı, Yorumları - Trendyol